HD Plasma Cutting: Technology & Applications

High-definition or HD plasma cutters are set apart from standard cutters not only by the technology they use, but also by the quality, accuracy, and speed of the cuts they produce. Even if cut quality isn’t high on your list of priorities, it’s vital to know about these tools if you do decide to expand or upgrade your production line.

What is HD plasma cutting?

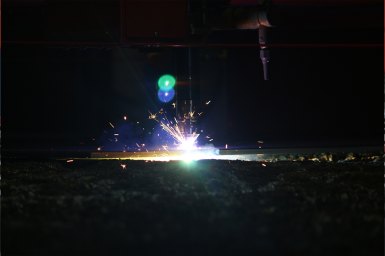

The HD plasma cutting process uses a jet of ionised gas at temperatures above 20,000°C to melt and expel material when forming the desired cut. This type of metal cutting works best on thicknesses between 3mm and 25mm.

How does HD plasma cutting work?

High-def plasma cutting works in the following way: The ionised gas jet expels pressurised gas such as oxygen, air, nitrogen, or a mix of gases at high speed. While this happens, the plasma cutter channels an electrical arc through the gas flow to transform the gas into plasma. The plasma reaches temperatures hot enough to cut right through metal at a pace fast enough to expel the molten metal from the cut.

.webp)