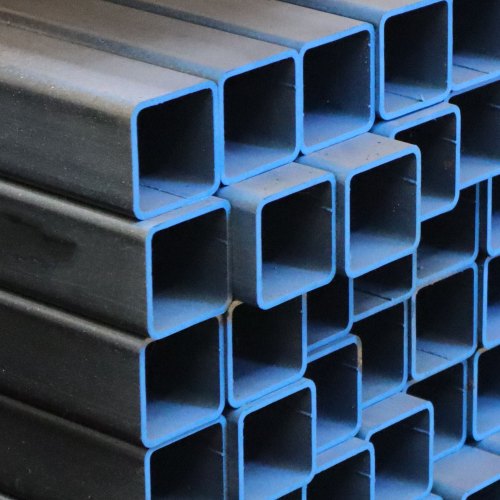

Steel hollow sections are a fundamental component in modern construction, engineering, and fabrication. Designed for strength, versatility, and efficiency, they provide structural integrity while maintaining a lightweight profile. To accommodate different environments, we offer various finishes, including plain, primed, and galvanised coatings, enhancing corrosion resistance and extending service life.

IMS supplies steel hollow sections that comply with British and international standards, ensuring high performance and reliability. Our expert team is available to assist with material selection, sizing, and technical specifications to help you find the best solution for your project.

Why Choose IMS Hollow Sections?

- High strength-to-weight ratio – Offers excellent load-bearing capacity without excessive weight.

- Structural versatility – Suitable for applications in construction, manufacturing, and mechanical engineering.

- Corrosion resistance – Available in coated and galvanised finishes for improved longevity in harsh environments.

- Ease of fabrication – Can be welded, cut, and drilled to suit complex project specifications.

We supply structural hollow sections in a variety of grades and finishes, ensuring you get the right material for your project.