Shotblasting is an important part of preparing materials, following a process where tiny abrasive elements are blasted with force to a metal’s top layer. This helps to improve its qualities, toughness, and aesthetics.

While painting steel isn’t absolutely necessary after shot blasting, applying paint afterwards then stops the metal from rusting and provides a cleaner finish.

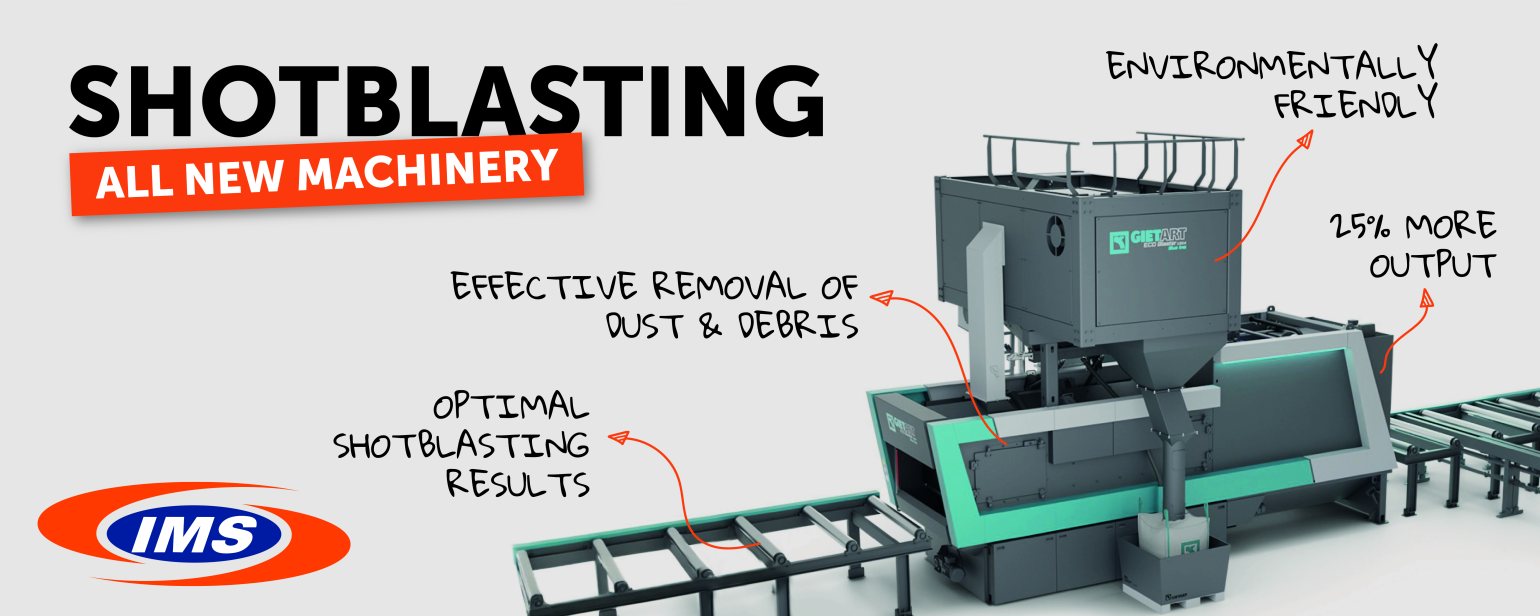

Shotblasting and painting, a versatile and highly effective preparation method, has revolutionised the way we maintain the structural integrity and enhance the longevity of metal work. A good finish requires effective preparation. Our shotblast services remove rust and scale quickly and efficiently to SA 2.5, delivering a high-quality surface preparation that is ready for future treatment.

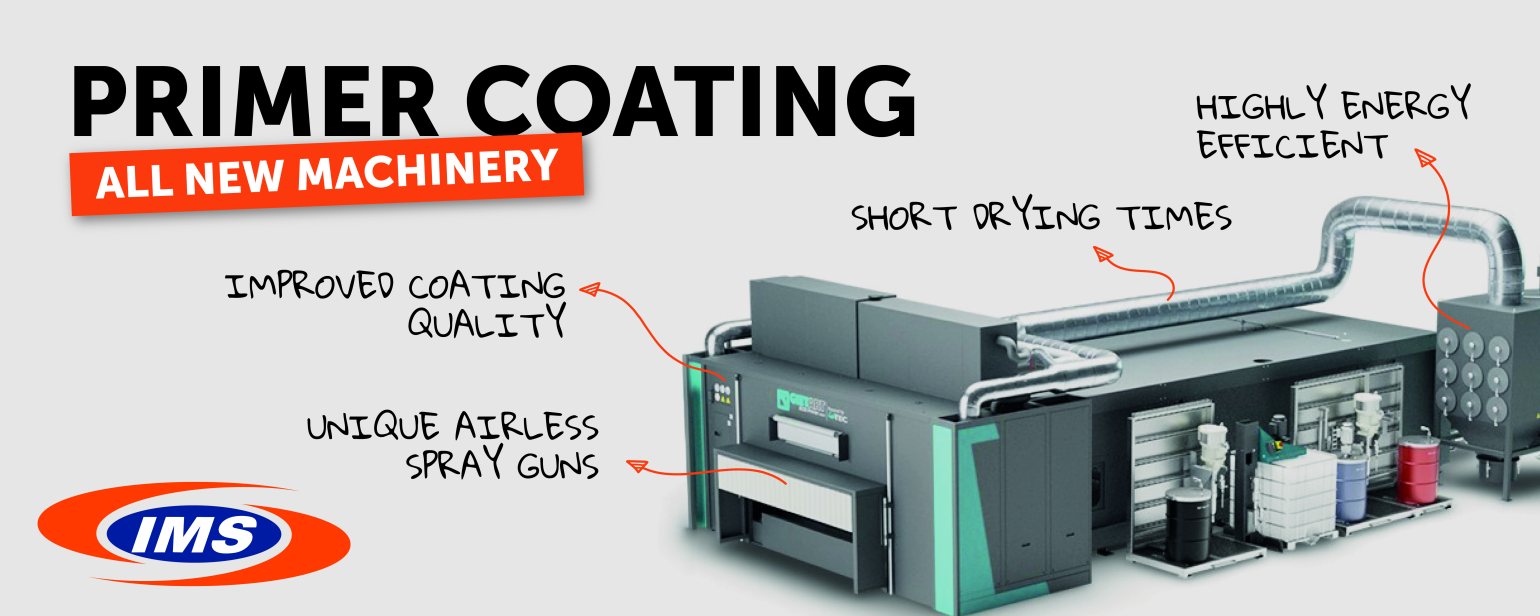

Our water-based primer is fast-drying, ensuring that we can process your steel quickly. The process delivers temporary protection against corrosion for steel constructions and cast iron.

We can deliver your product unpainted (shotblast only) to SA 2.5 or finish it in a choice of red or grey with a minimum of 25 microns. Should you require a thicker coat of paint, please ask one of our sales reps for more information.

Enquire TodayThe Gietart is a cutting edge shotblaster which prioritises efficiency and the environment while maintaining product quality. Designed to ensure an optimal process flow paired with highly efficient surface treatment inturn helps make it the most effective production of sophisticated, sustainable steel product.

18,300mm

Max. Length

500mm

Max Profile Height

1,500mm

Max Profile Width

2,500mm

Min. Length

6mm

Min. Thickness

SA2.5

Shotblasting

On the tail end of the Gietart is a painting assembly boasting highly efficient coating techniques for the protection of sophisticated, sustainable steel product. Developed to protect your steel products, the Gietart Eco Primer takes care of complete in-line primer coating.

Red

Min. 25 Microns

4

Spray Guns

Grey

Min. 25 Microns